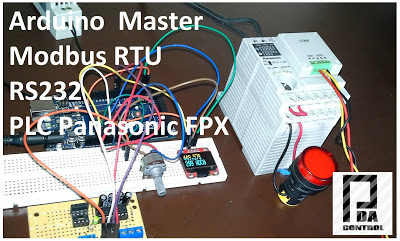

This time I have communicated the Arduino with Panasonic PLC and I checked the Arduino useful in the industrial field direfencia of the previous tutorials I’ve tested both devices communicating via RS – 232.

Summary

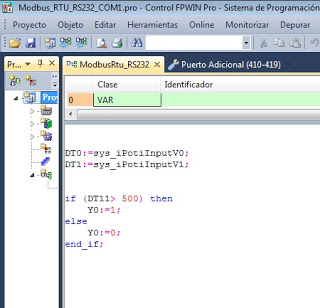

1. The arduino send via modbus ADC value 0 to Holding Register 0 and the plc into a strategy compared as follows Arduino

If ADC> 500

relay output PLC = 1

else

PLC relay output = 0

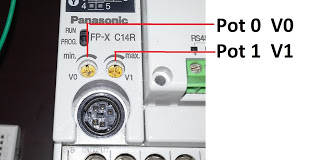

2. The PLC send the value 2 of its potentiometers from 0 to 1000 and displayed on the display arduino Oled, the respective values

Programmable Logic Controller used in industrial in this case the family FPX panasonic (Aromat – Nais)

This PLC has Modbus RTU protocol as master and slave To configure a teacher must create a strategy, if set as slave does not require code as the default plc is a slave and records are automatically routed.

DT0 = Holding Register [0]

DT1 = Holding Register [1]

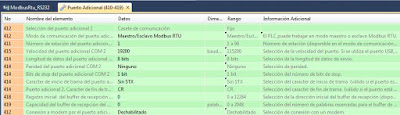

The control strategy of these PLC is done in the FPWIN Pro software:

Serial Ports settings

Arduino code

The arduino is configured as RTU Master to read and write 10 – 10 Holding Registers

Part 1 Arduino Modbus RTU Master

Video Final Test With Panasonic PLC

Github Code ARDUINO

https://github.com/JhonControl/Arduino_Modbus_Master_in_5_minutes

Instructables

http://www.instructables.com/id/Arduino-Modbus-Master-RTU-and-PLC-Panasonic-FPX-C1